There has been a lot of talk about how to make buildings more energy-efficient lately and like a lot of other states, Wisconsin recently approved the new 2015 International Energy Code. The requirements and contents within this code are of course driven by people passionate about reducing energy usage and greenhouse gas emissions. After all, buildings are responsible for about 40% of all energy consumption in the US. Therefore, reducing the amount of energy buildings use will reduce overall energy consumption and greenhouse gas emissions. Unfortunately, it’s not this simple and I’m not sure anyone has really done all the math to show that putting all this mostly-oil-based insulation on your house is really going to pay off. For example, calculations used to determine energy efficiency of a house are based on the ubiquitous “r-value” but the r-value only measures the transfer of energy through a material and not the ability of a material to store energy, which is important. While most softwoods generally have an R-value of around 1.4 per inch and hardwoods around .71 per inch, the value of wood as insulation goes beyond the ability to resist the transfer of heat.

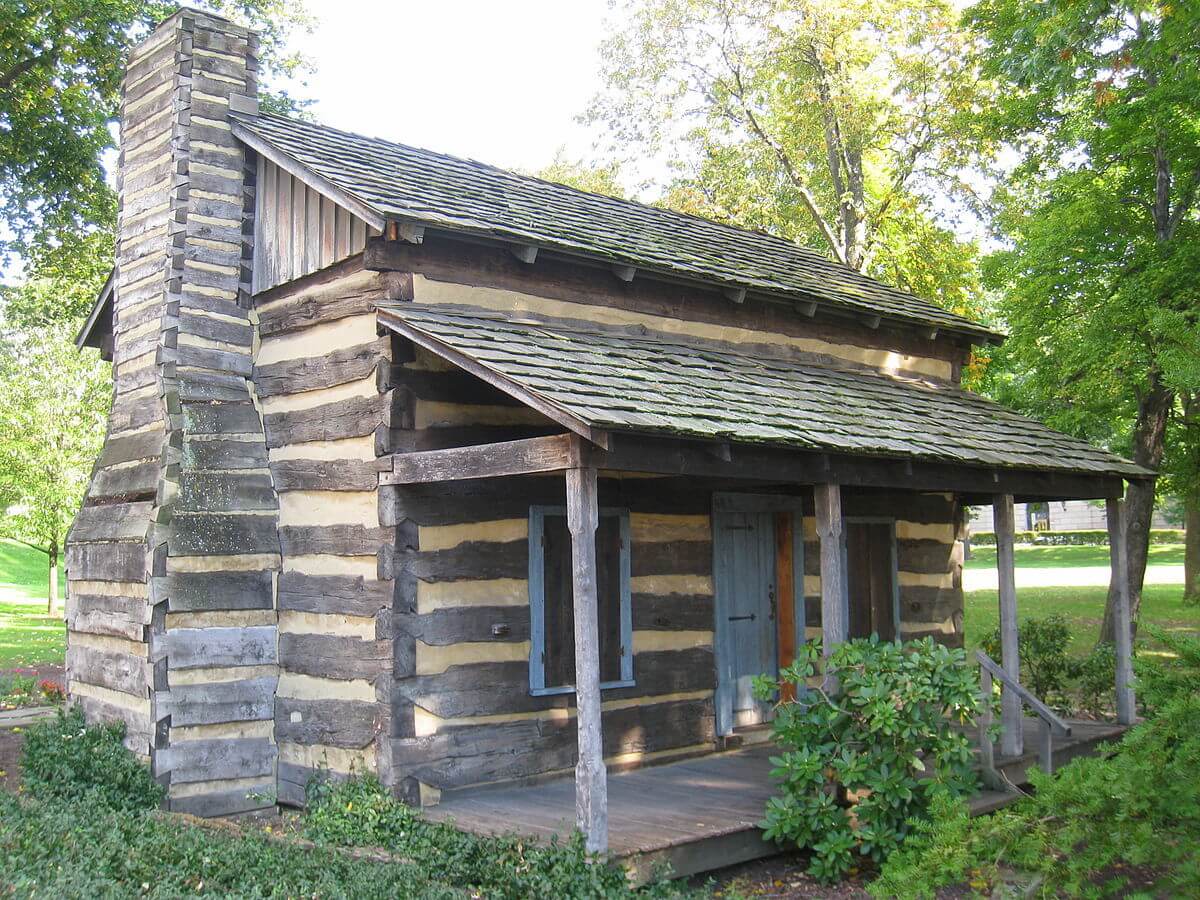

Brick, stone and concrete are known to be excellent stores of heat. The concept is that these materials trap the heat from the sun during the day, preventing it from heating your house too much, and then release it slowly during the night, thereby moderating the energy differentials between day and night. Surprisingly, solid wood has over 2.5 times the thermal mass of concrete. (reference) At what thickness would a solid wood wall be more efficient than a conventional ‘stick-built’ stud framed wall with batt insulation? This gets even more complicated because the answer depends on the location of the home and its climate and the orientation of the wall, among other things like amount of people living in the home, the level of humidity within, the heating and cooling sources used, and even the feeling and perception of the space having a solid wood wall vs. drywall, plastic and a little bit of wood.

Joe B.

One major change with the new energy code you hear a lot of architects, builders and developers griping about is the requirement to add ‘continuous insulation’ on the exterior of the building wall. This generally means a whole secondary layer of insulation, usually accompanied by another layer of framing, onto the outside of the building wall. But it also takes a lot of energy to make all that additional material and install it. Thankfully, Wisconsin allows an exception to the new energy code wherein if you can show that your building passes a simple energy loss calculation (ComCheck and ResCheck software models) you can potentially avoid installing continuous insulation.

A typical wall assembly using continuous insulation is like this: Inside of building / gypsum board (drywall) / vapor barrier / wood studs @ 16” on center with batt insulation between / plywood / house wrap / 1- 2” rigid insulation (oil based) sheets with wood or metal framing between / siding / outside of building. Theoretically, this assembly would have an R-value of about 30. But that does not take into account the thermal storage properties of the wall, the breaks in insulation caused by electrical and other receptacles buried in the batt insulation, the thermal bridging caused by the studs and other framing, the thermal bridging caused by the many fasteners, and the risk of trapping moisture within the wall assembly. That is a lot of effort and energy to put together a wall which still depends on assumptions of moisture retention and near perfection on placement of receptacles and fasteners to avoid thermal bridging and air leakage. Drywall is built with by-products of coal fired power plants. The vapor barrier and continuous insulation are built from oil. Compare that to an assembly like this: inside of building / wood / outside of building. Sure the r-value isn’t as high, but the assembly is much simpler, there is much less energy to make the material and install it, there is no thermal bridging, air pockets or gaps in the assembly, and the wall actually has a significant value as a store of energy and moderator of the thermal environment within the home. Not to mention the potential psychological and emotional value of having a beautiful wood wall vs. a drywall box.